| Siūlome | ||

|---|---|---|

|

| Terminis Pernešimas |

|

|

|

| Technologijos | |

| Sunday, 24 February 2008 22:10 | |

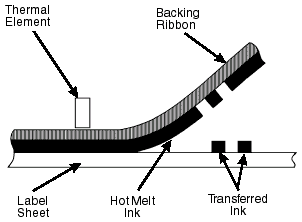

Thermal transfer printerFrom Wikipedia, the free encyclopediaA thermal transfer printer is a printer which prints on paper (or some other material) by melting a coating of ribbon so that it stays glued to the material on which the print is applied. It contrasts with Direct Thermal printing where no ribbon is present in the process[1]. Usage of TT printers in industry includes:

Barcode printers typically come in fixed sizes of 4 inches, 6 inches or 8 inches wide. Although a number of manufacturers have made differing sizes in the past, most have now standardised on these sizes. The main application for these printers is to produce barcode labels for product and shipping identification. The printers use a fixed width thermal print head, pressing onto a paper or plastic label, over a driven rubber roller called a platen. Between the print head and the label is sandwiched a very thin thermal transfer ribbon (or sometimes called "foil"), which is a polyester film which has been coated on the label side with a wax, wax-resin or pure resin "ink". The ribbon is spooled onto reels up to 625 meters (1965 feet) long and is driven through the printing mechanism in sync with the labels, at speeds of up to 12 inches per second (although 6 inches per second is adequate for most applications). As the label and ribbon are driven beneath the printhead together, tiny pixels across the width of the printhead are heated and cooled so as to melt the "ink" off the polyester film and onto the label. This process happens very quickly and accounts for the fast speed of the printers and is dry instantly. Thermal printheads are often 203 dots per inch (8 dots per mm) or 300 dpi (12 dots per mm). Though some manufacturers now make 600 dpi printers to produce very small barcodes for electronics industries (look inside the battery compartment of your mobile phone.) Because of the high print speeds, the label printers have become very sophisticated, with powerful processors and large memory capacities, to allow them to produce the label images to be printed at the same speed as the print mechanism. To achieve this speed, almost all thermal label printers use special internal description languages to allow the label to be laid out inside the printers' memory prior to printing. Each manufacturer has their own language and some are very complex and difficult to work with. For example to print a barcode on a label, the controlling computer would send a series of codes to the printer, requesting a particular barcode type and specifying its size and location on the label, along with the data to be printed as a barcode. The printer will then use pre-defined algorithms to construct the barcode, keeping very strictly to the resolution allowed by the printhead, to create the best possible barcode on that particular type of printer. Barcodes have very strict rules for accurate printing, to ensure readability in a wide range of circumstances.

[edit] LabelsLabels come in two main types: Thermal (sometimes referred to as Direct Thermal) and Thermal Transfer. A huge variety of special materials and adhesives are available to suit most applications. These include plain white paper packaging labels, durable rating plates, and tamper-evident labels. [edit] Thermal ribbonsThermal ribbons come in three main types - wax, wax-resin or pure resin and are almost always black (other colors sometimes used are red and blue). These different types are made to print onto different label materials and are used when the life of the label needs to be long or the labels needs to survive harsh environments. Wax ribbons are for printing onto paper labels, where the life of the label can be years but must be kept dry and must not be abraded or subjected to certain chemicals or oil, which would melt the wax image. Wax-resin ribbons product a finer image on very smooth paper or coated paper labels. The printed image is much more durable than wax, but can still only stand slight contact with water. Finally pure resin ribbons are formulated to print onto plastic labels such as polyester, polypropylene and vinyl. The "ink" is designed to slightly dissolve into or adhere to the plastic surface of the label and becomes extremely durable, depending on the plastic material and ribbon make used. Most printer manufacturers offer ribbon/label combinations which are known to work well together, which is particularly important as some combinations produce no image at all. Plastic labels with resin ribbons will survive outside in full sunlight, can stand immersion in water and may be resistant to chemicals and oils dependent on type. Often used in Automotive and Aircraft parts manufacture, any items stored outside and essential for the labelling of hazardous chemicals which must remain identifiable, for example, after being submerged in sea water for extended periods. [edit] Color thermal printersThermal printing technology can be used to produce color images by adhering a wax-based ink onto paper. As the paper and ribbon travel in unison beneath the thermal print head, the wax-based ink from the transfer ribbon melts onto the paper. When cooled, the wax is permanently adhered to the paper. This type of thermal printer uses a like-sized panel of ribbon for each page to be printed, regardless of the contents of the page. Monochrome printers have a black panel for each page to be printed, while color printers have either three (CMY) or four (CMYK) colored panels for each page. Unlike dye-sublimation printers, these printers cannot vary the dot intensity, which means that images must be dithered. Although acceptable in quality, the printouts from these printers cannot compare with modern inkjet printers and color laser printers. Currently, this type of printer is rarely used for full-page printing, and is now employed for industrial label printing due to its waterfastness and speed. These printers are considered highly reliable due to their small number of moving parts. Printouts from color thermal printers are sensitive to abrasion, as the wax ink can be scraped, rubbed off, or smeared. [edit] Tektronix/Xerox Solid-Ink PrintersSo-called "Solid-Ink" or "Phaser" printers were developed by Tektronix and later by Xerox (who acquired Tektronix's printer division). Printers like the Xerox Phaser 8400 uses 1 in³ rectangular solid-state ink blocks (similar in consistency to candle wax) which are loaded into a system similar to a stapler magazine in the top of the printer. The ink blocks are melted and the ink is transferred onto a rotating, oil coated print drum using a piezo inkjet head. The paper then passes over the print drum, at which time the image is transferred, or transfixed, to the page. This system is similar to water-based inkjets, provided that the ink has low viscosity at the jetting temperature (140C). Printout properties are similar to those mentioned above, although these printers can be configured to produce extremely high-quality results and are far more economical, as they only use the ink needed for the printout, rather than an entire ribbon panel. Costs of upkeep and ink are comparable to color laser printers, while 'standby' power usage can be very high, about 200W. [edit] ALPS MicroDry PrintersMicroDry is a computer printing system developed by the ALPS corporation of Japan. It is a resin-transfer system using individual colored thermal ribbon cartridges, and can print in process color using cyan, magenta, yellow, and black cartridges, as well as such spot-color cartridges as white, metallic silver, and metallic gold, on a wide variety of paper and transparency stock. Certain MicroDry printers can also operate in dye sublimation mode, using special cartridges and paper. |

|

| LAST_UPDATED2 |

| Kaip dirbame |

|---|

|

Siekiame, kad gaminių ir prekių kokybė visuomet tenkintų užsakovą. Būtent dėl to labai atsakingai renkamės žaliavas ir įrangą. Žinoma, esant poreikiui galime pasiūlyti ir puikios kainos gaminių, kurie taip pat pasižymi gerais kokybės rodikliais. Būtent dėl šių priežasčių, prieš pateikdami komercinį pasiūlymą, įsigiliname į kiekvieno užsakovo poreikius ir pateikiame atskirą optimalų sprendimą. |

| www.satinas.lt |

|---|

|